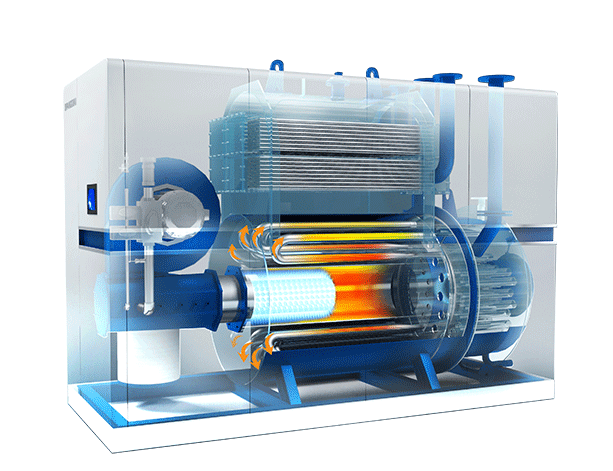

Vacuum Hot Water Boiler (T6)

Thermal power: 700~2800 KW

Thermal efficiency: >105%

Introduction:Fangkuai T6 Vacuum Hot Water Boiler is the upgrade generation adopting Ultra-speed smoke cooling tube. In this model, we also adopt U-type Fire Tube and full pre-mixed combustion technique. Gathering those high technologies, Fangkuai T6 Vacuum Hot Water Boiler can achieve better using effect, bring users much convenience, saving users much expend.

Chat Online Messages EmailFeatures

01

Efficient and low emission

The use of full premixed combustion technology makes fuel combustion more efficient, fuel utilization efficiency is higher, NOx emissions can be lower than 18mg/Nm3, far more than Europe and the United States and other countries; at the same time, the exhaust gas temperature is also reduced.

02

Strong dirt holding capacity

The cooling water flows outside the heat transfer tube, is not easy to scale and is easy to clean; the wing tube adopts a large volume design, and the heat exchange efficiency is not attenuated for a long time, the cooling water flow is also very smooth, and it is difficult to scale.

03

One machine can be used

The boiler adopts the universal standard pipe box. One boiler can adapt to different operation modes such as single circuit and double circuit, large temperature difference and small temperature difference, and can realize multi-channel water supply at the same time; the use is more flexible.

Product profile and dimension drawing

Parameterss

| Item | Fangkuai super-cooling vacuum boiler | Normal vacuum boiler |

| Heat exchanger structure | Straight tube could be washed easily from doors of the ends of water room; no damage to heat exchanger | U-type tube is hard to wash; huge damage to heat exchanger |

| Heat transfer technique | Special material plus special structure design make heat transfer area 5 times bigger; high efficiency | Normal material and structure leads higher smoke temperature; low efficiency |

| Test method | Helium Mass SpectrometerLeakDetector; Less than 3×10-8m³pa/s | Water leak detection; About 1.3~5.4×10-4 m³pa/s |

| Safety device | Mechanical safety device; Explosion-proof valve; Reliable work |

Electrical control device; Solenoid valve; Unstable operation |

| High efficiency condenser | Made of silicon-aluminum alloy; Not easy to scale and easy to clean; Long service life | Traditional fin tube; Easy scaling but not easy to clean; Short service life |

| Packaging appearance | Square structure; Movable door; Easy removal; | Lack of movable door; Hard removal; |

Comparison between super-cooling vacuum boiler and normal vacuum boiler |

|||||||||

| Thermal rating(×104 kcal/h) | Capacity (ton/h) |

Normal vacuum boiler consumption | Super-cooling vacuum boiler consumption |

Super cooling vacuum boile gas saved per hour |

Annual money saved (Annual operation time as 7000 hours) |

||||

|---|---|---|---|---|---|---|---|---|---|

| Natrual gas(Nm³/h) | Coal gas(Nm³/h) | Natrual gas(Nm³/h) | Coal gas(Nm³/h) | Natrual gas(Nm³/h) | Coal gas(Nm³/h) | Natrual gas(Nm³/h) | Coal gas(Nm³/h | ||

| 60 | 1 | 76.7 | 171.6 | 67.87 | 151.8 | 8.9 | 19.8 | 18.7 | 13.9 |

| 90 | 1.5 | 115.1 | 257.4 | 101.8 | 227.7 | 13.3 | 29.7 | 27.9 | 20.8 |

| 120 | 2 | 153.5 | 343.2 | 135.7 | 303.6 | 17.7 | 39.6 | 37.2 | 27.7 |

| 180 | 3 | 230.2 | 514.9 | 203.6 | 455.5 | 26.6 | 59.4 | 55.8 | 41.6 |

| 240 | 4 | 306.9 | 686.5 | 271.5 | 607.3 | 35.4 | 79.2 | 74.3 | 55.4 |

| 300 | 5 | 383.6 | 858.1 | 339.4 | 759.1 | 44.3 | 99.0 | 93.0 | 69.3 |

| 360 | 6 | 460.4 | 1029.7 | 407.2 | 910.9 | 53.1 | 118.8 | 111.5 | 83.2 |

| 480 | 8 | 613.8 | 1373.0 | 543.0 | 1214.6 | 70.8 | 158.4 | 148.7 | 110.9 |

| 600 | 10 | 767.3 | 1716.2 | 678.7 | 1518.2 | 88.5 | 198.0 | 185.9 | 138.6 |

| Calculating statment | Taking 3 USD/Nm³ as gas price, take 7000 hours as boiler annual running time | ||||||||

Attention:Take 8500 Kcal/Nm³ as gas calorific value. Unit price is 3 USD.

| Model | Length(mm) | Width(mm) | Height(mm) | Rated thermal power(kW) | Rated working pressure(Mpa) | Rated steam temperature(℃) | Rated pressure of heat exchanger(Mpa) | Thermal efficiency(%) | Hot water quantity t/h(10/60℃) |

| T6-700 | 3150 | 1350 | 2300 | 700 | -0.02 | 93.5 | 1.6 | 105.5 | 12 |

| T6-700 | 3570 | 1550 | 2330 | 1400 | -0.02 | 93.5 | 1.6 | 105.5 | 24 |

| T6-700 | 4910 | 1730 | 2680 | 2800 | -0.02 | 93.5 | 1.6 | 105.5 | 48 |

| Model | Single tube box | Two boxes in series | Two boxes in parallel | ||||||

| Rated heating capacity(MW) | Rated/imported water temperature(℃) | Hot water flow(m³/h) | Rated heating capacity(MW) | Rated/imported water temperature(℃) | Hot water flow(m³/h) | Rated heating capacity(MW) | Rated/imported water temperature(℃) | Hot water flow(m³/h) | |

| T6-700 | 0.47 | 60/50 | 40 | 0.7 | 60/40(80/60) | 30 | 0.7 | 60/50 | 60 |

| 60/40 | 20 | ||||||||

| T6-700 | 0.93 | 60/50 | 80 | 1.4 | 60 | 1.4 | 120 | ||

| 60/40 | 40 | ||||||||

| T6-700 | 1.87 | 60/50 | 160 | 2.8 | 120 | 2.8 | 240 | ||

| 60/40 | 80 | ||||||||

∗Take 38.3MJ/Nm³ as the low calorific value of natural gas

∗As the technology is constantly updated, it is subject to change without notice. For detailed parameters, please refer to the headquarters of Fangkuai Boiler co., LTD.

MESSAGES

PLEASE FEEL FREE TO LEAVE ANY MESSAGE THAT YOU WANT TO KNOW!