The benefits of WNS Gas heating Boiler

1. Advanced steam gas heating boiler automatic controller, full Chinese LCD screen, man-machine interface, user only need to easily set, gas heating boiler can start and stop according to user requirements, load regulation, automatic water supply and other automatic operation. Gas heating boiler has complete function, complete protection, simple operation, safety and reliability, and has the function of self-diagnosis. Once the abnormal phenomenon occurs in the operation of gas heating boiler, the combustion is automatically interrupted and the acousto-optic alarm is sent out.

2. The combustor of gas heating boiler is supplied by the world famous manufacturer. According to the instruction of the controller, it burns automatically and stops. The independent program controller has many kinds of safety protection, the performance is safe and stable, and the maintenance rate is low.

3. The vertical steam-gas heating boiler adopts the lower position mode of combustion machine, the two-way structure, the fuel combustion is sufficient, and the operation of gas-fired heating boiler is stable. The smoke pipe is inserted with spoiler to slow down the smoke exhaust speed, increase the heat transfer, high thermal efficiency of gas heating boiler, and reduce the cost of user use.

4. The horizontal steam gas heating boiler is a shell type full wet backflow three return fireworks tube structure. The flame burns under positive pressure in the large combustion chamber, completely extends, the combustion heat load is low, the combustion thermal efficiency is high, and the exhaust smoke temperature is effectively reduced. Energy saving and consumption reduction, use economy. The structure of waveform furnace tank and threaded smoke pipe not only improves the endothermic strength of gas heating boiler, but also meets the needs of heat transfer surface heat expansion, scientific and reasonable, durable.

5. This gas heating boiler strictly follows the rules for Safety Supervision of Steam Gas heating Boiler, JB/T 10094 / 2002 General Technical conditions for Industrial Gas heating Boiler, The requirements of JB/T 1619 / 2002 "Manufacturing Technical conditions of Boiler body for Gas heating Boiler" are carried out to ensure that the quality of gas heating boiler is good, the energy consumption is low, the thermal efficiency is high, the pressure is stable, the gas supply is sufficient, and the economic use is carried out.

6. The furnace space of gas heating boiler is large, the steam stored is more, and the ability to adapt to load is strong. Design a reasonable built-in steam separator to meet the requirements of high quality steam. The furnace body is equipped with manhole, head hole and hand hole, which is convenient to clean up the inside of the furnace tank and make the maintenance and maintenance very convenient.

7. the gas heating boiler is safely equipped with multistage interlocking protection: pressure switch protection (automatic shutdown above the set pressure and alarm), low water level protection (the water level in the gas heating boiler body is lower than the warning water level, automatically cut off the power supply and alarm), Safety valve protection (gas heating boiler pressure exceeds working pressure, automatic gas release and pressure reduction) to ensure that gas heating boiler is safe and safe under all kinds of working conditions.

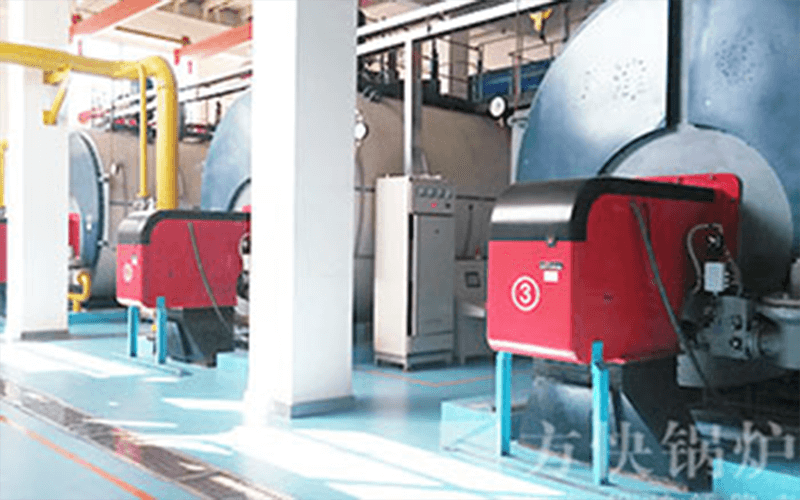

8, the organic combination of mechatronics appearance, exquisite and novel, compact structure, less space, convenient transportation, installation.

9, using new thermal insulation materials and high quality white color steel plate packaging, light weight, good thermal insulation performance, beautiful and generous, not easy to rust.