Matters needing attention in use of condensing Boiler

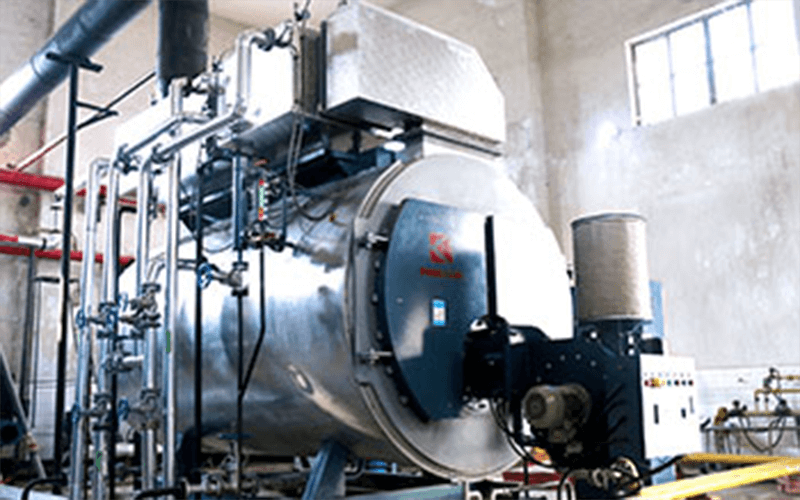

The condensing boiler can recover the residual heat in the high temperature flue gas of the boiler and the latent heat part of the steam condensation in the flue gas in order to improve the service efficiency and reduce the harmful gas in the flue gas. So it will soon become the future development direction of boiler technology. Driven by this new form, consumers also buy condensing boilers in succession, so in the use of condensing boilers, what aspects do consumers need to pay attention to in the use of condensing boilers?

First, pay attention to cleaning

The main function of corrosion inhibitor in cleaning process is to prevent metal corrosion during pickling of condensing boiler. In most cases, many people choose to use their eyes to detect whether the cleaning of condensing boiler is qualified or not. However, visual inspection can only see whether the cleaning is clean, ignoring the most important indicators of cleaning-the corrosion rate and the amount of corrosion. The rate of corrosion and the amount of corrosion is invisible to the naked eye. Therefore, consumers should also know how to measure the rate of corrosion and the amount of corrosion; in the cleaning process, the use of down-in, up-out or up-in-out circulation mode, the installation of temporary cleaning circulation pipeline in multiple locations, so that the pot, drum, pyrotechnic pipe, The riser, the descending pipe and the header can be circulating by cleaning pump to keep the concentration of cleaning fluid balanced, which can make the insoluble matter discharge from the boiler after cleaning and prevent a large amount of dirt from falling off and accumulating so as to prevent the "tube burst" accident of the boiler caused by a large amount of dirt falling off and accumulating.

2. In case of any of the following conditions in operation of the condensing boiler, the furnace shall be shut down immediately

The water level of the condensing boiler furnace is lower than the lowest visible edge of the water level gauge; the water level of the condensing boiler is continuously increased and other measures are taken, but the water level of the condensing boiler continues to drop; Water pump failure or water supply system failure cannot feed water into condensing boiler; condensing boiler level meter or safety valve is all invalid; condensing boiler components are damaged and the safety of operators is endangered.

Therefore, when consumers choose and use direct-selling condensing boilers from manufacturers, they not only need to carry out standardized operations in accordance with the operating instructions, but also need to pay more attention to matters needing attention in the use of condensing boilers. In this way, consumers can use condensing boiler process to double insurance, avoiding the risk in the process of operation.

What is the advantage of condensing boiler compared to ordinary boiler

In the boiler market, a kind of boiler product called "condensing" boiler is popular, then, what are the outstanding points of this kind of condensing boiler, and what are its advantages compared with the ordinary boiler?

1. As the name implies, a condensing boiler is a boiler that adopts condensation technology. By means of a condensing device, the flue gas discharged from the boiler is retreated with residual heat, making full use of the latent heat released by the sensible heat in the exhaust smoke and the condensation of steam into water droplets. In order to achieve the purpose of improving boiler thermal efficiency.

The exhaust gas temperature of the conventional boiler is about 160 ℃ and 250 ℃. The steam in the flue gas is still in the overheated state and has a large amount of unused heat. Generally speaking, the thermal efficiency of boiler is calculated according to the low heating value of fuel, and the latent heat of vaporization in the high heating value of fuel is not taken into account, so the thermal efficiency of traditional boiler can only reach 87% / 91%. The condensing boiler with condensing technology also reclaims the latent heat of vaporization from the flue gas emitted from fuel combustion, and reduces the exhaust temperature to 50 ℃ and 70 ℃, and the boiler heat efficiency is also increased. If the efficiency of ordinary boilers is generally about 93% The condensation furnace technology can increase it by 15%, and it can reach 108% or so. Such energy-saving, efficient and environmentally friendly boilers are bound to lead the development of boiler industry in the future.

Taking natural gas fuel as an example, the high-level heat generation is about 9500kcal/m ³and the low-level heat generation is about 8600kcal/m ³, a difference of about 900kcal/m ³, accounting for 11% of the low-level calorific value. Therefore, choosing condensing boiler will reduce gas operation cost by about 11% compared with ordinary boiler. (see for more information on high and low calorific values)

Second, condensing boilers are more environmentally friendly. Compared with traditional coal-fired boilers, condensing boilers generally use clean and environmentally friendly natural gas as fuel, and the exhaust gas generated by boiler operation is greatly reduced, thus alleviating the emissions of sulfur oxides, nitrogen oxides, dust and other harmful substances in the air of cities and towns. It is the pioneer boiler product of green environment protection.

Fangkuai Boiler has many years of research and design experience in condensing boilers. The thermal efficiency of condensing series boiler products produced can reach 107%, and nitrogen oxide emissions can be less than 30 mg / m3. At the same time, it is safe and convenient to use and has a long life. Furnace operation heat loss and other advantages, once put into the market has been widely loved and used by users.

If your company is looking for a new type of energy-saving, environmentally-friendly, efficient boiler equipment, welcome to contact us through the 0371x55629010 toll-free hotline.