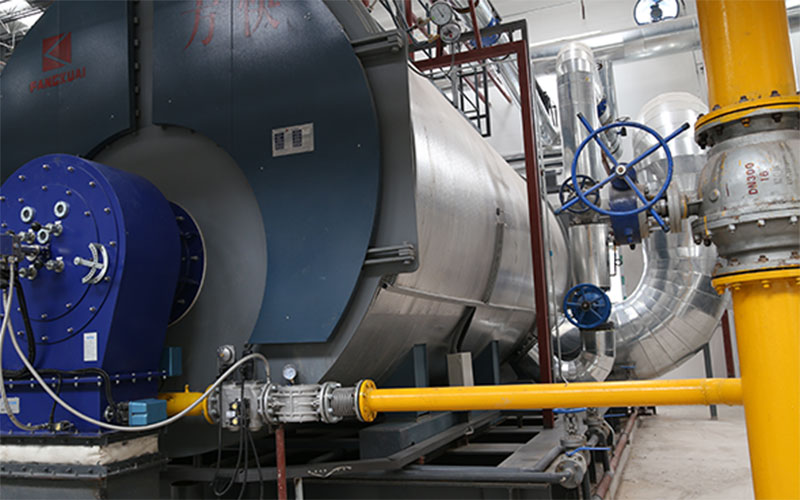

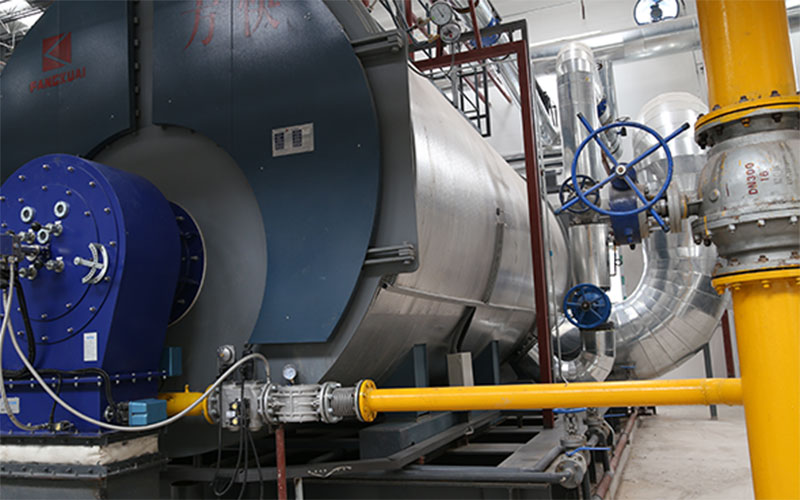

Gas fired heating boilers water pressure test steps and precautions

Gas fired heating boilers are often used in living, commercial, etc., commonly used gas hot water boilers. Under normal circumstances, the water pressure test is required before and after the installation of the gas heating boiler. So what are the steps? What are the precautions?

Gas fired heating boiler water pressure test steps and precautions

1. The pressure of the water pressure test is 1.05Mpa.

2. The water filling speed should not be too fast, when the boiler is full of water. When the highest point air valve has not exhausted air, close the bleed valve. Wipe the water tsraces taken away during deflation, and initially check the parts of the water filling. If there is a leak, it should be treated.

3. Boost should be slow. When the pressure rises to 0.39Mpa (the gauge pressure, the voltage regulator is fully inspected. The leakage of the manhole and the hand hole flange bolt can be tightened. If there is serious water leakage, stop the water pressure test and repair the hand hole and flange bolt. For leaks, tighten the bolts. If there is serious water leakage, stop the water pressure test and repair it before performing the water pressure test.

4. When the pressure rises to the working pressure, stop the boost and thoroughly check the leak. Then rise to the test pressure for 5 minutes, reduce to the working pressure, check, and meet the following conditions.

A. Under test pressure, hold for 20 minutes, then lower to working pressure for inspection, and the pressure should remain constant during the inspection.

B. There is no leakage at the weld.

5. After passing the water pressure test, the water pressure test shall be signed. The water in the boiler should be specially designed to release water and discharge all the water in the system. There are antifreeze measures in winter.

6. notes:

A. During the pressure test, all work related to the pressure test around the pressure system should be stopped.

B. Test pressure under test pressure should be done as little as possible. Generally, the pressure test is performed under working pressure.

C. When draining, pay attention to open the top valve to ensure that all water in the system is drained.

D. During the hydrostatic test, after the pressure exceeds 0.39Mpa, it is not allowed to tighten the bolts to make up the leak.

E. Repair welding of welds, it is not advisable to carry water, and repair welding should be penetrated. Do not weld. Weld seams at critical locations where leaks are severe. The original weld should be shoveled and re-welded.

5. After passing the water pressure test, the water pressure test shall be signed. The water in the boiler should be specially designed to release water and discharge all the water in the system. There are antifreeze measures in winter.

6. notes:

A. During the pressure test, all work related to the pressure test around the pressure system should be stopped.

B. Test pressure under test pressure should be done as little as possible. Generally, the pressure test is performed under working pressure.

C. When draining, pay attention to open the top valve to ensure that all water in the system is drained.

D. During the hydrostatic test, after the pressure exceeds 0.39Mpa, it is not allowed to tighten the bolts to make up the leak.

E. Repair welding of welds, it is not advisable to carry water, and repair welding should be penetrated. Do not weld. Weld seams at critical locations where leaks are severe. The original weld should be shoveled and re-welded.

5. After passing the water pressure test, the water pressure test shall be signed. The water in the boiler should be specially designed to release water and discharge all the water in the system. There are antifreeze measures in winter.

6. notes:

A. During the pressure test, all work related to the pressure test around the pressure system should be stopped.

B. Test pressure under test pressure should be done as little as possible. Generally, the pressure test is performed under working pressure.

C. When draining, pay attention to open the top valve to ensure that all water in the system is drained.

D. During the hydrostatic test, after the pressure exceeds 0.39Mpa, it is not allowed to tighten the bolts to make up the leak.

E. Repair welding of welds, it is not advisable to carry water, and repair welding should be penetrated. Do not weld. Weld seams at critical locations where leaks are severe. The original weld should be shoveled and re-welded.