Analysis of related problems of Water Collector for heating Hot Water Boiler

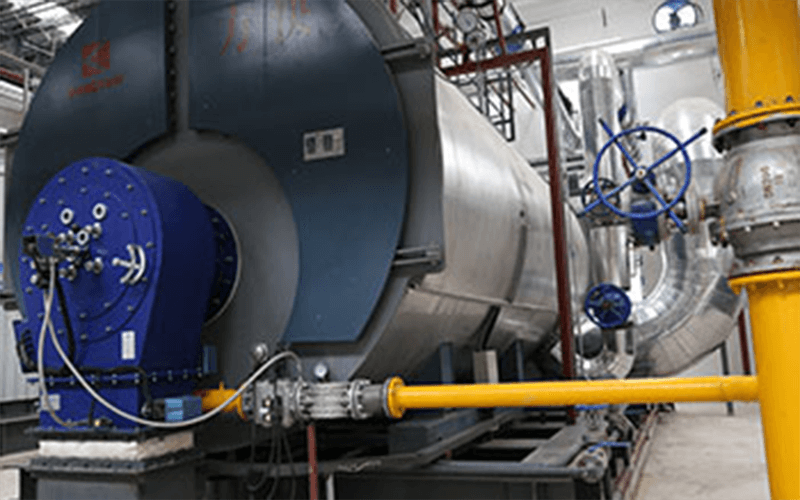

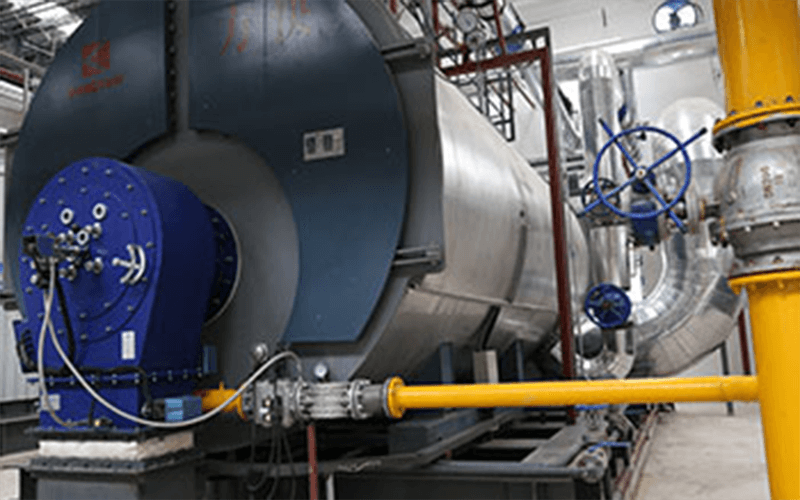

The water collector is used in the water system to connect the heating pipe supply, the return water distribution and the water collecting device. According to the intake and return water divided into water separator, water collector. It is the main supporting equipment of the heating hot water boiler, which is used to distribute the steam produced by the heating hot water boiler to each pipeline, and the divided cylinder is the pressure bearing equipment, which belongs to the pressure vessel and its pressure bearing capacity. The capacity should correspond to the matching heating hot water boiler. The main pressure components of the water collector are: head, shell material and so on.

The classification of water collector is as follows:

1. Basic type: it is composed of main pipe of water separation and main pipe of collecting water. Ball valves are installed at each branch port of the water collecting main pipe, and manual exhaust valves are arranged on the water collecting main pipe. The basic water divider does not have the function of flow regulation.

2. Standard type: the standard collector has the same structure as the basic type, except that the ball valve on each main pipe is replaced by the flow regulating valve. Replace the manual exhaust valve on the two main pipes with the automatic exhaust valve. The standard collector can adjust the flow rate of each loop precisely, and even the flow regulation of the luxury standard collector can realize the artificial intelligence regulation.

3, functional type: the functional collector not only has all the functions of the standard water collector, but also has the functions of temperature and pressure display, automatic flow adjustment, automatic mixing heat transfer and thermal energy metering. Indoor zone temperature automatic control function, wireless and remote control function.

The material structure of the water collector of the heating hot water boiler is as follows:

In order to prevent corrosion, water collector is usually made of corrosion-resistant metal or synthetic material. Common materials are copper, stainless steel, copper nickel plating, alloy nickel plating, high temperature resistant plastics and so on. The inner and outer surface of the water collector (including connectors, etc.) should be smooth and clean, without cracks, sand eyes, cold insulation, slag clamping, uneven and other defects, and the surface electroplating connectors should be uniform in color, solid in coating and no defects in de-plating.

Application of water collector:

A water collector is a device that outputs multiple influents all the way through a container. It manages a number of branch pipelines, including backwater branch and water supply branch, most of which are different from DN350-DN1500, made of carbon steel or stainless steel plate, belonging to the professional manufacture of pressure vessels, it needs to install pressure meter thermometer. On the one hand, the water flow of the main pipe is distributed according to the needs, so as to ensure the flow of each regional branch loop to meet the load needs, and at the same time, the flow of each branch loop is collected and input back into the main water pipe to realize the cycle operation. The reuse of backwater can achieve more energy saving effect and can be full at the same time. It is widely used in heating hot water boiler, central air conditioning, industrial circulating cooling water system and hot water system.

The classification of water collector is as follows:

1. Basic type: it is composed of main pipe of water separation and main pipe of collecting water. Ball valves are installed at each branch port of the water collecting main pipe, and manual exhaust valves are arranged on the water collecting main pipe. The basic water divider does not have the function of flow regulation.

2. Standard type: the standard collector has the same structure as the basic type, except that the ball valve on each main pipe is replaced by the flow regulating valve. Replace the manual exhaust valve on the two main pipes with the automatic exhaust valve. The standard collector can adjust the flow rate of each loop precisely, and even the flow regulation of the luxury standard collector can realize the artificial intelligence regulation.

3, functional type: the functional collector not only has all the functions of the standard water collector, but also has the functions of temperature and pressure display, automatic flow adjustment, automatic mixing heat transfer and thermal energy metering. Indoor zone temperature automatic control function, wireless and remote control function.

The material structure of the water collector of the heating hot water boiler is as follows:

In order to prevent corrosion, water collector is usually made of corrosion-resistant metal or synthetic material. Common materials are copper, stainless steel, copper nickel plating, alloy nickel plating, high temperature resistant plastics and so on. The inner and outer surface of the water collector (including connectors, etc.) should be smooth and clean, without cracks, sand eyes, cold insulation, slag clamping, uneven and other defects, and the surface electroplating connectors should be uniform in color, solid in coating and no defects in de-plating.

Application of water collector:

A water collector is a device that outputs multiple influents all the way through a container. It manages a number of branch pipelines, including backwater branch and water supply branch, most of which are different from DN350-DN1500, made of carbon steel or stainless steel plate, belonging to the professional manufacture of pressure vessels, it needs to install pressure meter thermometer. On the one hand, the water flow of the main pipe is distributed according to the needs, so as to ensure the flow of each regional branch loop to meet the load needs, and at the same time, the flow of each branch loop is collected and input back into the main water pipe to realize the cycle operation. The reuse of backwater can achieve more energy saving effect and can be full at the same time. It is widely used in heating hot water boiler, central air conditioning, industrial circulating cooling water system and hot water system.

The classification of water collector is as follows:

1. Basic type: it is composed of main pipe of water separation and main pipe of collecting water. Ball valves are installed at each branch port of the water collecting main pipe, and manual exhaust valves are arranged on the water collecting main pipe. The basic water divider does not have the function of flow regulation.

2. Standard type: the standard collector has the same structure as the basic type, except that the ball valve on each main pipe is replaced by the flow regulating valve. Replace the manual exhaust valve on the two main pipes with the automatic exhaust valve. The standard collector can adjust the flow rate of each loop precisely, and even the flow regulation of the luxury standard collector can realize the artificial intelligence regulation.

3, functional type: the functional collector not only has all the functions of the standard water collector, but also has the functions of temperature and pressure display, automatic flow adjustment, automatic mixing heat transfer and thermal energy metering. Indoor zone temperature automatic control function, wireless and remote control function.

The material structure of the water collector of the heating hot water boiler is as follows:

In order to prevent corrosion, water collector is usually made of corrosion-resistant metal or synthetic material. Common materials are copper, stainless steel, copper nickel plating, alloy nickel plating, high temperature resistant plastics and so on. The inner and outer surface of the water collector (including connectors, etc.) should be smooth and clean, without cracks, sand eyes, cold insulation, slag clamping, uneven and other defects, and the surface electroplating connectors should be uniform in color, solid in coating and no defects in de-plating.

Application of water collector:

A water collector is a device that outputs multiple influents all the way through a container. It manages a number of branch pipelines, including backwater branch and water supply branch, most of which are different from DN350-DN1500, made of carbon steel or stainless steel plate, belonging to the professional manufacture of pressure vessels, it needs to install pressure meter thermometer. On the one hand, the water flow of the main pipe is distributed according to the needs, so as to ensure the flow of each regional branch loop to meet the load needs, and at the same time, the flow of each branch loop is collected and input back into the main water pipe to realize the cycle operation. The reuse of backwater can achieve more energy saving effect and can be full at the same time. It is widely used in heating hot water boiler, central air conditioning, industrial circulating cooling water system and hot water system.