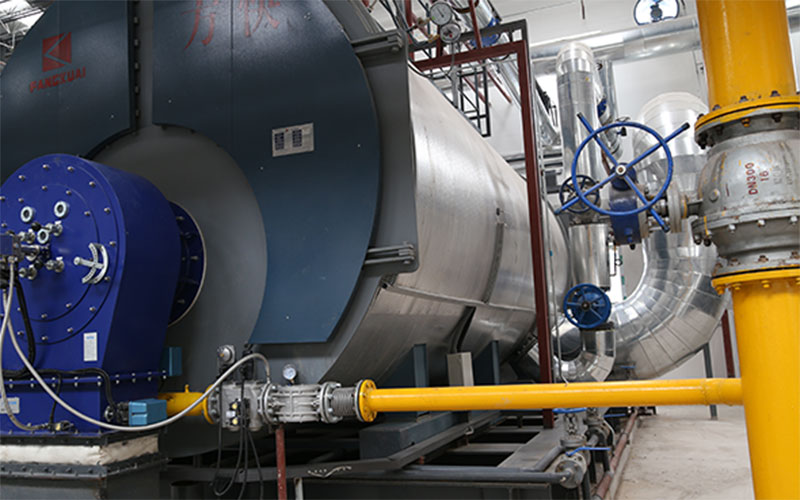

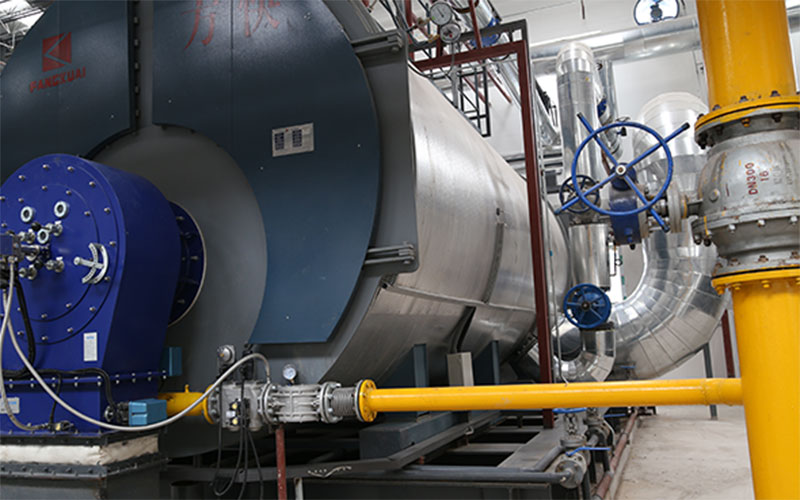

Waste heat utilization of gas heating boiler

Waste heat recovery space

As the coal of the heating boiler is changed, the gas boiler is more and more used as a distributed heat source. The gas will release a lot of heat after the boiler is burned, but the heat that can be utilized by the traditional gas boiler is only a part. There is a lot of heat that is wasted with the exhaust gas temperature. Under normal circumstances, the exhaust gas temperature of ordinary natural gas boilers is generally 120 to 200 C, and these flue gases contain 8% to 15% of sensible heat and 11% of latent heat of water vapor. Many people have the impression that in the winter, the smoke around the boiler house is smog. This is because natural gas contains a lot of hydrogen and burns a lot of water vapor. When the exhaust gas temperature is high, the water vapor condenses after the outdoor cold air, and as the flue gas is discharged, a "white smoke" is formed. The main purpose of the gas waste heat recovery equipment equipped with a flue gas condenser is to convert the water vapor in the flue gas into condensed water through the condenser, and to maximize the recovery of latent heat and sensible heat contained in the flue gas, so that the heat is recovered after the heat is exhausted. The temperature can be reduced to about 25 �� C, such as the exhaust gas temperature from 160 �� C to 25 �� C, which means that the heat generated in the middle of 135 �� C can be recycled, energy-saving energy.

Recycling meaning

(1) Water saving. At the same time of heat recovery, a large amount of condensed water is produced, and 100kg of condensed water is produced per ton of steam per hour. This water is burned, contains a small amount of acidic substances, is neutralized and filtered by alkali, and can be used for boiler hydration or other industrial purposes (to 10 For example, a ton of boilers has an annual operating time of 150 days, and 3,600 tons of water can be recycled throughout the year.

(2) Reduction of emissions. The harmful components of flue gas in natural gas are mainly water vapor, nitrogen monoxide and nitrogen dioxide. Nitric oxide can be converted into nitrogen dioxide by oxidation, and nitrogen dioxide is dissolved in condensed water, which can greatly reduce harmful components in gas boiler flue gas emissions. It is a simple, efficient and low-cost gas boiler denitration mode.

As the coal of the heating boiler is changed, the gas boiler is more and more used as a distributed heat source. The gas will release a lot of heat after the boiler is burned, but the heat that can be utilized by the traditional gas boiler is only a part. There is a lot of heat that is wasted with the exhaust gas temperature. Under normal circumstances, the exhaust gas temperature of ordinary natural gas boilers is generally 120 to 200 C, and these flue gases contain 8% to 15% of sensible heat and 11% of latent heat of water vapor. Many people have the impression that in the winter, the smoke around the boiler house is smog. This is because natural gas contains a lot of hydrogen and burns a lot of water vapor. When the exhaust gas temperature is high, the water vapor condenses after the outdoor cold air, and as the flue gas is discharged, a "white smoke" is formed. The main purpose of the gas waste heat recovery equipment equipped with a flue gas condenser is to convert the water vapor in the flue gas into condensed water through the condenser, and to maximize the recovery of latent heat and sensible heat contained in the flue gas, so that the heat is recovered after the heat is exhausted. The temperature can be reduced to about 25 �� C, such as the exhaust gas temperature from 160 �� C to 25 �� C, which means that the heat generated in the middle of 135 �� C can be recycled, energy-saving energy.

Recycling meaning

(1) Water saving. At the same time of heat recovery, a large amount of condensed water is produced, and 100kg of condensed water is produced per ton of steam per hour. This water is burned, contains a small amount of acidic substances, is neutralized and filtered by alkali, and can be used for boiler hydration or other industrial purposes (to 10 For example, a ton of boilers has an annual operating time of 150 days, and 3,600 tons of water can be recycled throughout the year.

(2) Reduction of emissions. The harmful components of flue gas in natural gas are mainly water vapor, nitrogen monoxide and nitrogen dioxide. Nitric oxide can be converted into nitrogen dioxide by oxidation, and nitrogen dioxide is dissolved in condensed water, which can greatly reduce harmful components in gas boiler flue gas emissions. It is a simple, efficient and low-cost gas boiler denitration mode.

As the coal of the heating boiler is changed, the gas boiler is more and more used as a distributed heat source. The gas will release a lot of heat after the boiler is burned, but the heat that can be utilized by the traditional gas boiler is only a part. There is a lot of heat that is wasted with the exhaust gas temperature. Under normal circumstances, the exhaust gas temperature of ordinary natural gas boilers is generally 120 to 200 C, and these flue gases contain 8% to 15% of sensible heat and 11% of latent heat of water vapor. Many people have the impression that in the winter, the smoke around the boiler house is smog. This is because natural gas contains a lot of hydrogen and burns a lot of water vapor. When the exhaust gas temperature is high, the water vapor condenses after the outdoor cold air, and as the flue gas is discharged, a "white smoke" is formed. The main purpose of the gas waste heat recovery equipment equipped with a flue gas condenser is to convert the water vapor in the flue gas into condensed water through the condenser, and to maximize the recovery of latent heat and sensible heat contained in the flue gas, so that the heat is recovered after the heat is exhausted. The temperature can be reduced to about 25 �� C, such as the exhaust gas temperature from 160 �� C to 25 �� C, which means that the heat generated in the middle of 135 �� C can be recycled, energy-saving energy.

Recycling meaning

(1) Water saving. At the same time of heat recovery, a large amount of condensed water is produced, and 100kg of condensed water is produced per ton of steam per hour. This water is burned, contains a small amount of acidic substances, is neutralized and filtered by alkali, and can be used for boiler hydration or other industrial purposes (to 10 For example, a ton of boilers has an annual operating time of 150 days, and 3,600 tons of water can be recycled throughout the year.

(2) Reduction of emissions. The harmful components of flue gas in natural gas are mainly water vapor, nitrogen monoxide and nitrogen dioxide. Nitric oxide can be converted into nitrogen dioxide by oxidation, and nitrogen dioxide is dissolved in condensed water, which can greatly reduce harmful components in gas boiler flue gas emissions. It is a simple, efficient and low-cost gas boiler denitration mode.