Economic Analysis of Oil-fired Hot water Boiler heating

Economic Analysis of Oil-fired Hot water Boiler heatingHeating equipment is the wintering artifact of people in the north of China, the winter without heating equipment is easy to come out of people, together with our common heating equipment are mainly coal-fired boilers, but now people's requirements for the environment are gradually oil-fired boilers. Instead of gas-fired boiler, what people pay more attention to is the running cost of gas-fired boiler heating. In this article, we make an economic analysis on the running cost of fuel-fired boiler heating. Heating heat load list name production users and public residential buildings subtotal area M3 load KW

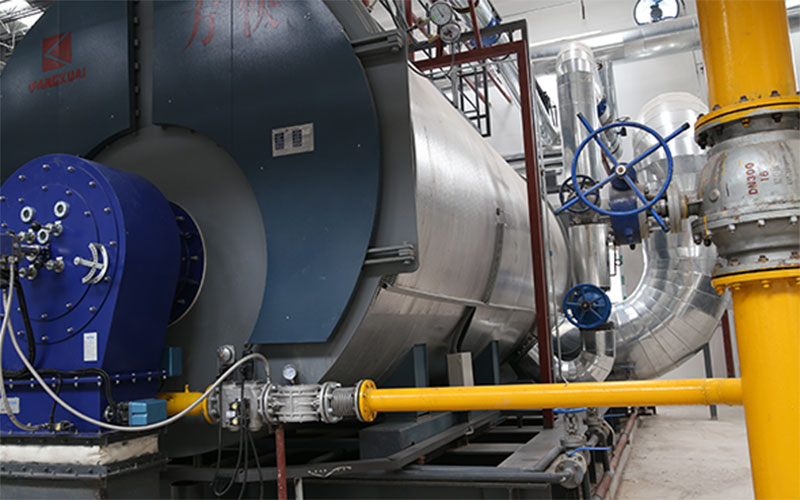

4, the selection of heat source equipment Kurle city is a new oil city is also a national green In order to keep the city green and the air from being polluted, the furnace body of coal-fired boiler and (n) oil-fired boiler is compact in structure, small in volume, light in weight and small in area. On the computer room height requirements are not large, easy to integrate with residential buildings, saving investment. The price of oil-fired boiler is a little higher, but the thermal efficiency is as high as 90%, the supporting facilities are simple, only need the equipment such as oil storage tank, oil pump, pipeline, daily use box and so on, and the one-time investment cost is lower. The operation automation degree is high, the work is safe and reliable. Operating under low pressure, the use of which does not fall within the monitoring scope of the boiler and pressure vessel safety monitoring rules, but does not have a full-time operation Management personnel, save the cost of manager I exhaust smoke in the dust. The content of harmful gas is low, the environmental protection effect is good, the degree of blackness of Ringman is grade, the concentration of sulfur dioxide is 5mg / m3, which is lower than the requirement of the emission standard of boiler air pollutant (GB13271-91). Two WNSY-180 oil-fired boilers are selected after study. The technical parameters are: rated output 2000kW, thermal efficiency 90%, fuel clean-up) pressure; WIM sub-interchanger for heating and hot water heating system diagram, in the early winter operation of an oil-fired hot water boiler, when outdoor degree will be-VC--13'C, a When two oil-fired hot-water boilers can not meet the load, two oil-fired hot-water boilers can close the other oil-fired hot-water boiler when the operation of the two oil-fired hot-water boilers can rise to-2'C--7C at the same time, when one oil-fired hot-water boiler can meet the load. Leave 1 for M / M: fuel oil for oil-fired hot water boiler. According to the heating diagram, the oil pump sends the oil from the outdoor oil storage tank to the indoor oil tank, and the excess oil flows back to the oil storage tank. The oil pump is controlled by the level controller of the indoor daily oil tank. The oil-fired hot water boiler is supplied with its own burners from the indoor daily fuel tank. B _ 2 fuel-fired M furnace fuel supply heating system indicated that the third, design characteristics: 1, combustion When the initial operation of the oil-fired boiler uses 10 light oil, when the hot water temperature in the boiler rises to 551 / 65, switch the heavy oil transmission valve and burn the heavy oil, this period of time will take 50 minutes and 65 minutes. The heat of the heating system is used to heat the heavy oil storage tank and the daily fuel tank, and the heavy oil is heated without electricity or other forms, so the investment is saved. Before shutting down the furnace, light oil valves should be switched over again, and light oil (5? 25 minutes) will be used to prevent the remaining heavy oil wax in the pipeline and affect the re-start of the oil-fired hot water boiler.

2 from the outdoor underground storage tank, the oil pump to the indoor oil-fired hot water boiler burner oil pipeline connection, transportation The oil pipeline is double-layer pipeline, the outer layer is heating water supply, the inner layer is heavy oil pipeline. This method ensures that the heavy oil is not waxed in the pipeline, so that the oil path is unimpeded and the operation safety 3. The heating load is used to exchange domestic hot water and indirect heating is adopted. The type of heat exchanger is plate heat exchanger. It not only satisfies the heating load of the peak heating season in winter, but also satisfies the needs of the residents of the residential district, and saves the heating equipment and running cost of the independent hot water. 4. Economic comparison of operating costs according to the distribution of the number of days of heating period, the new plant is divided into three districts, the city of Kurle is (1) district, the average outdoor degree during heating period -4T / m, the heating days are 126 days, the number of degree days is 2772Ddi, the running frequency of oil-fired hot water boiler is 16 hours with two shifts, and the working time is 48 days during the heating peak period. Daily hot water supply is twice a week, running time is 3.5 hours / time, hot water supply is 35 times during heating period. The repair of the source road, heavy oil supply situation is not normal. In 1999, the city of Kurle realized the gasification of natural gas supply, the oil-fired boiler in the district was replaced by natural gas heating, and the original oil storage tank was used as the reserve fuel for the peak period of natural gas use or the maintenance of natural gas equipment. Heating During the period, each shift will be used to keep a good record of light fuel, heavy oil and natural gas consumption per hour and total daily consumption, The operating costs of the three heating periods are as follows: light oil burning time Tl=65 minutes 25 minutes per day = 90 minutes = 1.5 hours light oil daily consumption Gl=180kgx, .5 small hours = 270kg/ day light oil daily cost ZI=G1x heating period Total light oil consumption EG1=G1x heating period light oil total cost EZ / Z1 heavy oil combustion time T _ 2 / day 16 hours-1.5 hours-14.5 hours heavy oil complementary combustion time T3 = 16 hours heavy oil consumption G 2 / day 14.5 hours x peak fuel consumption G3=I6 hours per day G3=I6 hours x 200kgx0.70=2240Ic days hot water every time heavy oil consumption G4 / 3.5 hours heating period fuel total 4 divisions nbsp; Analysis on operating cost of Z=EZ1 pure light oil combustion heating Gl=16 hour per day light oil consumption 16 hours per day light oil consumption per day hot water light oil consumption G3 / 3.5 hours x total light oil consumption during heating period EG heating total fuel consumption per day light oil consumption G3 / 3. 5 hours per day light oil consumption during heating period total light oil consumption during heating period EG total fuel consumption during heating period Cost Z=SGx heating period H2=Z/3 per square meter heating cost 4944M2=83.7? ten thousand yuan / 34944 yuan / 23. 96 yuan / M23, Analysis on the operating cost of natural gas heating the total cost of natural gas during the heating period of daily consumption of natural gas during the heating period is Z burning heavy oil and pure light oil. Percentage difference in operating costs of natural gas (?) percentage difference between burning heavy oil and burning light oil: (down 117 pages) 10mm2; The other one is 1200mm long, the air volume is 5000m3 / h, and the wind-outlet speed is 15mm2 / h; the latter air volume is twice as long as the former one, and the latter is twice the air outlet surface. The product is 1.33 times that of the former, so it is deduced that the output velocity of the latter is 2/l3=1.5 times that of the former, that is, from the basic concept of hydrodynamics, when the wind speed increases to 1.5 times, the resistance of the latter is about 2.25 times that of the original. At this point, the same fan can't have that much air volume. For example, a kind of air curtain of a sample indicates that the size of the tuyere is 100x1200mm, the air volume is 3000m5h. and the outlet speed is 9ms. It is not difficult to calculate that if the air volume data is correct, the outlet velocity is only 6.9m / s, and the sample data contradicts each other. The above-mentioned similar Samples abound. The unreliable information in the sample is bound to mislead the user.